Bumpers are the first things that come into contact when a vehicle collides with an obstacle. They are designed and manufactured in such a way that they can keep their functionality in the car.

Bumpers are present in a car to:

- Take the impact when a car collides and dampen it to comfort the passengers. They can be termed slow-speed crumple zones.

- Bumpers are designed to sacrifice themselves to protect the inner parts. They are designed in such a manner that the headlights and engine bay do not bear as much of an impact directly.

- They can help improve the drag coefficient if designed considering the car’s aerodynamics.

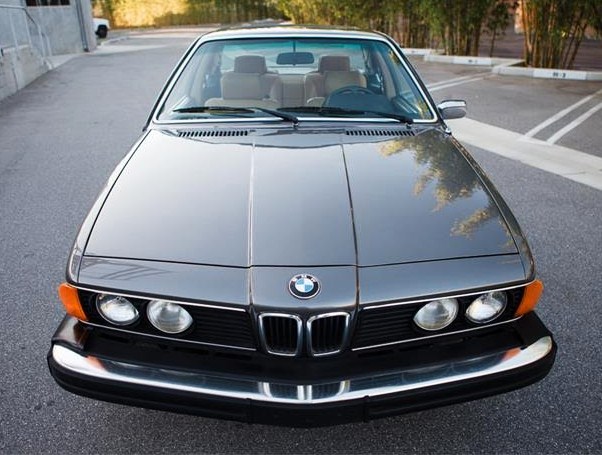

Cars used to come with solid steel bumpers back in the early days. Chrome bumpers were a trend in cars from the 70, 80s. With their added ruggedness, they had some serious flaws too. A solid steel bumper was not as much of a functional bumper. As when such vehicles had low speed frontal or rear collisions, these bumpers just transferred the force to the inner components, such as the engine bay or the car’s trunk.

To counter these flaws, in 1973, the US federal standard stated that a bumper should withstand an impact of 2.5mph at the front, and 05 mph at the rear. Although it was later eased up to 2.5mph at the front and rear, as sturdy as the metallic bumpers were, most of them ended up being bent easily.

It was at that time, when plastic bumpers started to become common. As bumpers were now made into two parts, a plastic outer molding, with a steel alloy beam underneath connected to the car’s frame.

Plastic bumpers did a great job on the outside, as they were very flexible, and could easily handle the routine nicks and bumps without any visible damage. Plastic bumpers are a lot cheaper to repair and fix, too. These bumpers also provided cushioning to headlights and inner operational parts from the lighter impacts. It also provided better resistance against scratching. Whereas a steel bumper tends to bend easily under concentrated impacts and is prone to corrosion and scratches.

Plastic bumpers had the potential to be shaped easily and mass manufactured at marginally lower costs. Plastic bumpers also provide pedestrian safety, which is regulated by modern safety regulation authorities.

Older steel bumpers were mostly press forged out of steel sheets. They were then treated with nickel plating to avoid corrosion and were finally chrome-plated to make them aesthetically pleasing.

Modern plastic bumpers are mostly made through reaction injection molding. A liquid mixture is pumped into the die/mold, where it cures and solidifies into solid plastic. Bumpers are usually made of ABS plastic and have steel beams behind them to take on heavier impacts.